With properly implemented AR, operators can see the health of their facilities and equipment more clearly and concisely. Data regarding the health of the operator’s equipment is converted to visual overlays seen on mobile devices. For instance, an operator can point a mobile device with an Index AR based application at a row of pumps. Data from the pumps can be converted to simple visual overlays, with an intuitive stoplight color coding to showcase pump information.

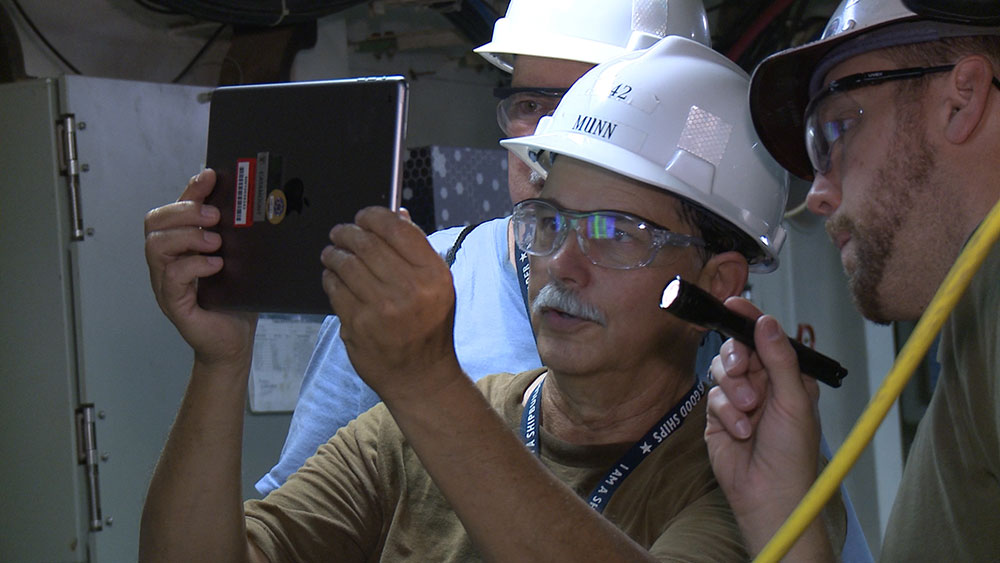

AR can also be vital for maintenance, especially in today’s industrial environment where knowledge transfer is extremely important for continuity of operations. Currently, industrial organizations face lopsided demographics with many skilled tradespeople preparing for retirement with no clear means to transfer job knowledge to newly hired craftspeople. With Index AR, this challenge is addressed.

Index AR applications transfer knowledge from experienced workers, extract information from technical documents, and incorporate observations from procedure reviews. All of this is converted to simple, easy-to-use visual step-by-step instructions overlaid directly on the equipment being maintained, improving safety, quality, cost, and schedule in the process. AR fundamentally changes the efficiency of maintenance operations and the way people train to maintain, shortening the learning cycle by many multiples.